Travertine, a luxurious natural stone, has adorned some of the world’s most iconic structures for centuries. Its journey began in the ancient quarries of Barco, near Tivoli, Italy, a story that intertwines with the rise and fall of empires, technological advancements, and an enduring legacy of beauty.

Ancient Roots: A Stone’s Tale

The Barco quarries, a treasure trove of Roman travertine, have been a vital source of this exquisite stone for over 2,000 years. Romans discovered the precious deposit in the 3rd century BC, its origins dating back to the Pleistocene era, over 100,000 years ago.

The formation of travertine is a fascinating process, a testament to the power of nature. Calcareous sediments, deposited over millennia, were molded into stone by the thermal springs of Tivoli. These sulphureous waters, known as Aquae Albulae, were cherished by the Romans for their healing properties, leading to the development of thermal structures in the area.

The ancient name of the quarries was Ager Tiburtinus, reflecting the valley below Tivoli, where the Romans quarried the stone. Travertine blocks were transported to Rome via the Via Tiburtina and the Aniene River. Ox-drawn wagons traversed the road, while wooden rafts, powered by the river’s current, carried the stone along its path.

The extraction methods of the Romans were a marvel of ingenuity. Pickaxes, wooden wedges, and chisels were used to carefully detach blocks from the rock face. This efficient technique enabled the Romans to utilize travertine extensively in their grand constructions.

From Ancient Wonders to Modern Marvels

Roman travertine played a pivotal role in shaping the Roman Empire. Monuments like the Colosseum, Marcellus Theater, Porta Maggiore, and the Temple of Claudius, stand as enduring testaments to the stone’s beauty and resilience.

Functional structures like aqueducts, and architectural elements including columns, thresholds, jambs, and architraves, also showcased the versatility of travertine. The opus quadratum technique, where travertine bricks were arranged in groups of four, was used for creating solid foundations for buildings.

Examples of travertine’s architectural brilliance can be found throughout Rome, from the city’s heart to the luxurious villas in the countryside. The temples at Tivoli’s Acropolis and mausoleums like the one dedicated to the Plauzi family, stand as elegant reminders of travertine’s enduring beauty.

A Renaissance of the Stone: The Barco Quarries Today

The fall of the Roman Empire brought about a decline in travertine mining, but its demand never fully waned. During the Middle Ages, recycled travertine was used, sadly causing damage to ancient structures.

The Barco quarries faced neglect, becoming a swamp due to the Aniene River’s floods. However, revival arrived in the 16th century with the construction of Saint Peter’s Basilica, where travertine was used extensively, as seen in the Basilica’s Colonnade.

The governor of Tivoli, Cardinal Ippolito II d’Este, transformed the ager tiburtinus into his personal hunting reserve, renaming it “Parco” (park) or “Barco.” This new name became synonymous with the travertine quarries, and they have been known as the Barco quarries ever since.

A Legacy of Innovation: From Oxcarts to Diamond Wires

The Barco quarries have witnessed technological advancements over the centuries. In the late 19th century, a tramway connecting Tivoli to Rome was built, allowing for the efficient transportation of travertine blocks. The early 20th century brought the introduction of helical wires powered by pulleys, making the extraction process faster, more precise, and less labor-intensive.

The Poggi family played a key role in transforming the land surrounding the quarries into a thriving travertine industry. In the early 20th century, the demand for travertine boomed, both for construction and decorative purposes. The Poggi Brothers helped build iconic structures like the fountain at Palazzo del Quirinale and the EUR district in Rome, using travertine as their signature material.

Since the 1960s, the Poggi Brothers have expanded their reach worldwide, collaborating with renowned architects on global projects. The Bank of China in Beijing, Apple Inc. headquarters in Seattle, and the Centre International de Conférences in Algiers are just a few examples of how travertine continues to grace the world’s architecture.

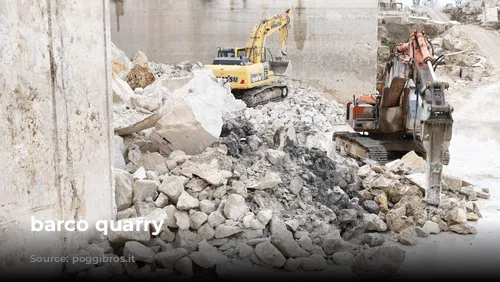

Innovation has been a driving force in the Barco quarries, with the introduction of diamond wires for cutting travertine. These cutting-edge techniques ensure precision and efficiency, while state-of-the-art machinery guarantees quality.

Embracing the Future: Industry 4.0 and Sustainability

The Barco quarries are embracing the future with a commitment to Industry 4.0, automating production processes and integrating machinery and data collection. This will enhance productivity and preserve the expertise of skilled travertine workers.

The environmental impact of travertine mining is also a priority. Mine backfilling is used to restore the natural landscape after extraction. The Barco quarries operate under strict environmental regulations, ensuring a sustainable future for the iconic travertine industry.

The history of the Barco quarries is a captivating tapestry woven from the threads of ancient Rome, technological advancements, and a dedication to artistry. As travertine continues to grace the world with its elegance and durability, it serves as a reminder of the timeless beauty of nature and the enduring legacy of human craftsmanship.